What are the Popular Capacitor Current Product Types?

I. Introduction

Capacitors are fundamental components in electrical and electronic systems, playing a crucial role in energy storage, filtering, and signal processing. They are essential in a wide range of applications, from consumer electronics to industrial machinery. This article aims to provide a comprehensive overview of the various types of capacitors, with a particular focus on popular capacitor current product types. We will explore the basics of capacitors, their classifications, and the factors influencing their selection, as well as future trends in capacitor technology.

II. Understanding Capacitor Basics

A. What is a Capacitor?

A capacitor is a passive electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store charge.

B. How Capacitors Work

Capacitors operate on the principle of charge storage. When connected to a power source, electrons accumulate on one plate, creating a negative charge, while the other plate loses electrons, resulting in a positive charge. The amount of charge a capacitor can store is measured in farads (F), with capacitance being a key parameter in determining its performance.

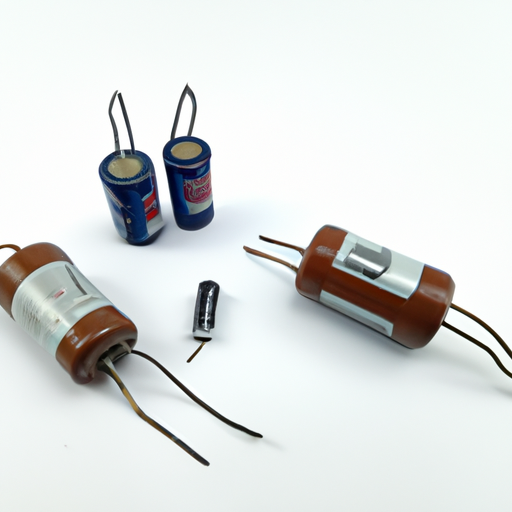

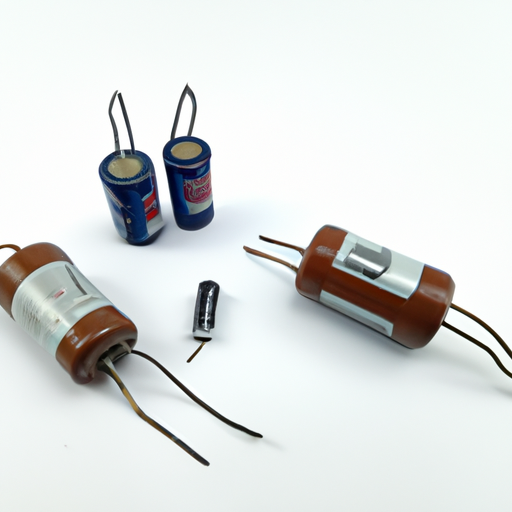

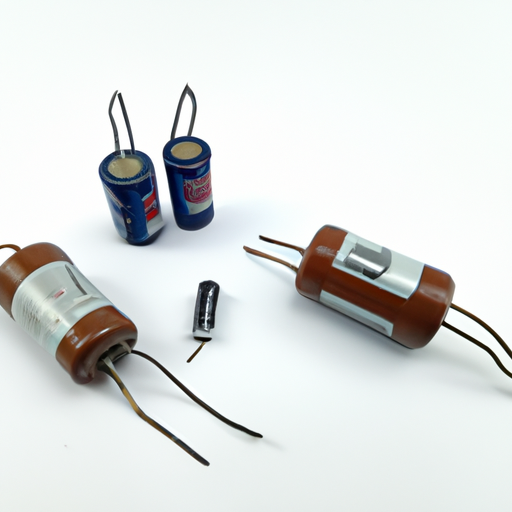

C. Types of Capacitors Based on Construction and Materials

Capacitors can be classified based on their construction and the materials used in their dielectric. Common types include electrolytic, ceramic, film, tantalum, and supercapacitors, each with unique characteristics and applications.

III. Types of Capacitors

A. Electrolytic Capacitors

Electrolytic capacitors are polarized capacitors that use an electrolyte as one of their plates. They are known for their high capacitance values and are commonly used in power supply circuits, audio equipment, and filtering applications. While they offer significant advantages, such as high capacitance in a small size, they also have disadvantages, including limited voltage ratings and a shorter lifespan compared to other types.

B. Ceramic Capacitors

Ceramic capacitors are non-polarized capacitors made from ceramic materials. They are available in two main classes: Class 1 (temperature stable) and Class 2 (high capacitance). Ceramic capacitors are widely used in high-frequency applications, decoupling, and filtering due to their low equivalent series resistance (ESR) and excellent stability.

C. Film Capacitors

Film capacitors are constructed using thin plastic films as the dielectric. They come in various types, including polyester, polypropylene, and polystyrene. Film capacitors are known for their stability, low losses, and high voltage ratings, making them suitable for applications in audio equipment, power electronics, and motor drives.

D. Tantalum Capacitors

Tantalum capacitors are another type of electrolytic capacitor, but they use tantalum metal as the anode. They are known for their high capacitance and reliability, making them ideal for applications in telecommunications, aerospace, and medical devices. However, they can be more expensive than other types of capacitors.

E. Supercapacitors

Supercapacitors, also known as ultracapacitors, are energy storage devices that bridge the gap between traditional capacitors and batteries. They have a very high capacitance and can store large amounts of energy, making them suitable for applications in renewable energy systems, electric vehicles, and backup power supplies.

IV. Capacitor Current Product Types

A. Current Rating and Its Importance

The current rating of a capacitor is a critical parameter that indicates the maximum amount of current the capacitor can handle without overheating or failing. Understanding the current rating is essential for ensuring the reliability and performance of the capacitor in its intended application.

B. Popular Capacitor Current Product Types

1. Low-Current Capacitors

Low-current capacitors are typically used in consumer electronics, such as smartphones, tablets, and audio devices. These capacitors are designed to handle small amounts of current, making them ideal for applications where space is limited. Examples of low-current capacitors include small ceramic capacitors and electrolytic capacitors used in signal processing.

2. Medium-Current Capacitors

Medium-current capacitors are commonly found in industrial applications, such as motor drives, power supplies, and lighting systems. These capacitors can handle moderate levels of current and are often used in applications that require stability and reliability. Examples include film capacitors and tantalum capacitors used in power electronics.

3. High-Current Capacitors

High-current capacitors are designed for demanding applications, such as power electronics, automotive systems, and renewable energy systems. These capacitors can handle significant amounts of current and are essential for applications that require rapid charge and discharge cycles. Examples include supercapacitors used in electric vehicles and high-power electrolytic capacitors used in power supply circuits.

4. Specialty Capacitors

Specialty capacitors are designed for niche markets and specific applications, such as medical devices, aerospace, and telecommunications. These capacitors may have unique characteristics, such as high-temperature stability or radiation resistance. Examples include high-voltage capacitors used in X-ray machines and capacitors designed for use in harsh environments.

V. Factors Influencing Capacitor Selection

When selecting a capacitor for a specific application, several factors must be considered:

A. Application Requirements

The intended application will dictate the type of capacitor needed. For example, high-frequency applications may require ceramic capacitors, while power supply circuits may benefit from electrolytic capacitors.

B. Environmental Considerations

Capacitors must be chosen based on the environmental conditions they will face, such as temperature, humidity, and exposure to chemicals. Some capacitors are designed to withstand harsh conditions, while others may have limitations.

C. Cost vs. Performance Trade-offs

Cost is always a consideration in capacitor selection. While high-performance capacitors may offer better reliability and efficiency, they can also be more expensive. Balancing cost and performance is crucial for achieving the best value.

D. Manufacturer Reputation and Reliability

Choosing capacitors from reputable manufacturers can ensure quality and reliability. Researching manufacturer specifications, reviews, and warranties can help in making informed decisions.

VI. Future Trends in Capacitor Technology

A. Innovations in Materials and Design

The capacitor industry is witnessing innovations in materials and design, leading to improved performance and efficiency. New dielectric materials and manufacturing techniques are being developed to enhance capacitance and reduce size.

B. The Role of Capacitors in Renewable Energy Systems

As the demand for renewable energy sources grows, capacitors play a vital role in energy storage and management systems. Supercapacitors and other advanced capacitor technologies are being integrated into solar and wind energy systems to improve efficiency and reliability.

C. Emerging Applications in Electric Vehicles and IoT

The rise of electric vehicles and the Internet of Things (IoT) is driving demand for advanced capacitor technologies. Capacitors are essential for energy storage, power management, and signal processing in these applications, leading to ongoing research and development in the field.

VII. Conclusion

Understanding the various types of capacitors and their current product types is essential for selecting the right component for specific applications. Capacitors play a critical role in modern electronics, and their importance will only continue to grow as technology advances. By considering application requirements, environmental factors, and manufacturer reliability, engineers and designers can make informed decisions that enhance performance and reliability in their projects. As capacitor technology evolves, ongoing research and exploration will be vital for harnessing the full potential of these essential components.

VIII. References

A comprehensive list of academic papers, articles, and resources for further reading, along with manufacturer websites and product catalogs, can provide additional insights into the world of capacitors and their applications.

What are the Popular Capacitor Current Product Types?

I. Introduction

Capacitors are fundamental components in electrical and electronic systems, playing a crucial role in energy storage, filtering, and signal processing. They are essential in a wide range of applications, from consumer electronics to industrial machinery. This article aims to provide a comprehensive overview of the various types of capacitors, with a particular focus on popular capacitor current product types. We will explore the basics of capacitors, their classifications, and the factors influencing their selection, as well as future trends in capacitor technology.

II. Understanding Capacitor Basics

A. What is a Capacitor?

A capacitor is a passive electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store charge.

B. How Capacitors Work

Capacitors operate on the principle of charge storage. When connected to a power source, electrons accumulate on one plate, creating a negative charge, while the other plate loses electrons, resulting in a positive charge. The amount of charge a capacitor can store is measured in farads (F), with capacitance being a key parameter in determining its performance.

C. Types of Capacitors Based on Construction and Materials

Capacitors can be classified based on their construction and the materials used in their dielectric. Common types include electrolytic, ceramic, film, tantalum, and supercapacitors, each with unique characteristics and applications.

III. Types of Capacitors

A. Electrolytic Capacitors

Electrolytic capacitors are polarized capacitors that use an electrolyte as one of their plates. They are known for their high capacitance values and are commonly used in power supply circuits, audio equipment, and filtering applications. While they offer significant advantages, such as high capacitance in a small size, they also have disadvantages, including limited voltage ratings and a shorter lifespan compared to other types.

B. Ceramic Capacitors

Ceramic capacitors are non-polarized capacitors made from ceramic materials. They are available in two main classes: Class 1 (temperature stable) and Class 2 (high capacitance). Ceramic capacitors are widely used in high-frequency applications, decoupling, and filtering due to their low equivalent series resistance (ESR) and excellent stability.

C. Film Capacitors

Film capacitors are constructed using thin plastic films as the dielectric. They come in various types, including polyester, polypropylene, and polystyrene. Film capacitors are known for their stability, low losses, and high voltage ratings, making them suitable for applications in audio equipment, power electronics, and motor drives.

D. Tantalum Capacitors

Tantalum capacitors are another type of electrolytic capacitor, but they use tantalum metal as the anode. They are known for their high capacitance and reliability, making them ideal for applications in telecommunications, aerospace, and medical devices. However, they can be more expensive than other types of capacitors.

E. Supercapacitors

Supercapacitors, also known as ultracapacitors, are energy storage devices that bridge the gap between traditional capacitors and batteries. They have a very high capacitance and can store large amounts of energy, making them suitable for applications in renewable energy systems, electric vehicles, and backup power supplies.

IV. Capacitor Current Product Types

A. Current Rating and Its Importance

The current rating of a capacitor is a critical parameter that indicates the maximum amount of current the capacitor can handle without overheating or failing. Understanding the current rating is essential for ensuring the reliability and performance of the capacitor in its intended application.

B. Popular Capacitor Current Product Types

1. Low-Current Capacitors

Low-current capacitors are typically used in consumer electronics, such as smartphones, tablets, and audio devices. These capacitors are designed to handle small amounts of current, making them ideal for applications where space is limited. Examples of low-current capacitors include small ceramic capacitors and electrolytic capacitors used in signal processing.

2. Medium-Current Capacitors

Medium-current capacitors are commonly found in industrial applications, such as motor drives, power supplies, and lighting systems. These capacitors can handle moderate levels of current and are often used in applications that require stability and reliability. Examples include film capacitors and tantalum capacitors used in power electronics.

3. High-Current Capacitors

High-current capacitors are designed for demanding applications, such as power electronics, automotive systems, and renewable energy systems. These capacitors can handle significant amounts of current and are essential for applications that require rapid charge and discharge cycles. Examples include supercapacitors used in electric vehicles and high-power electrolytic capacitors used in power supply circuits.

4. Specialty Capacitors

Specialty capacitors are designed for niche markets and specific applications, such as medical devices, aerospace, and telecommunications. These capacitors may have unique characteristics, such as high-temperature stability or radiation resistance. Examples include high-voltage capacitors used in X-ray machines and capacitors designed for use in harsh environments.

V. Factors Influencing Capacitor Selection

When selecting a capacitor for a specific application, several factors must be considered:

A. Application Requirements

The intended application will dictate the type of capacitor needed. For example, high-frequency applications may require ceramic capacitors, while power supply circuits may benefit from electrolytic capacitors.

B. Environmental Considerations

Capacitors must be chosen based on the environmental conditions they will face, such as temperature, humidity, and exposure to chemicals. Some capacitors are designed to withstand harsh conditions, while others may have limitations.

C. Cost vs. Performance Trade-offs

Cost is always a consideration in capacitor selection. While high-performance capacitors may offer better reliability and efficiency, they can also be more expensive. Balancing cost and performance is crucial for achieving the best value.

D. Manufacturer Reputation and Reliability

Choosing capacitors from reputable manufacturers can ensure quality and reliability. Researching manufacturer specifications, reviews, and warranties can help in making informed decisions.

VI. Future Trends in Capacitor Technology

A. Innovations in Materials and Design

The capacitor industry is witnessing innovations in materials and design, leading to improved performance and efficiency. New dielectric materials and manufacturing techniques are being developed to enhance capacitance and reduce size.

B. The Role of Capacitors in Renewable Energy Systems

As the demand for renewable energy sources grows, capacitors play a vital role in energy storage and management systems. Supercapacitors and other advanced capacitor technologies are being integrated into solar and wind energy systems to improve efficiency and reliability.

C. Emerging Applications in Electric Vehicles and IoT

The rise of electric vehicles and the Internet of Things (IoT) is driving demand for advanced capacitor technologies. Capacitors are essential for energy storage, power management, and signal processing in these applications, leading to ongoing research and development in the field.

VII. Conclusion

Understanding the various types of capacitors and their current product types is essential for selecting the right component for specific applications. Capacitors play a critical role in modern electronics, and their importance will only continue to grow as technology advances. By considering application requirements, environmental factors, and manufacturer reliability, engineers and designers can make informed decisions that enhance performance and reliability in their projects. As capacitor technology evolves, ongoing research and exploration will be vital for harnessing the full potential of these essential components.

VIII. References

A comprehensive list of academic papers, articles, and resources for further reading, along with manufacturer websites and product catalogs, can provide additional insights into the world of capacitors and their applications.