What are the Popular Shunt Capacitor Product Types?

I. Introduction

A. Definition of Shunt Capacitors

Shunt capacitors are electrical components that are used to improve the power factor in electrical systems. They are connected in parallel (or "shunt") with the load, providing reactive power compensation. This helps to reduce the overall demand for reactive power from the grid, leading to improved efficiency and reduced energy costs.

B. Importance of Shunt Capacitors in Electrical Systems

In modern electrical systems, maintaining an optimal power factor is crucial for efficient operation. Poor power factor can lead to increased energy losses, higher electricity bills, and potential penalties from utility companies. Shunt capacitors play a vital role in correcting power factor issues, enhancing voltage stability, and improving the overall performance of electrical systems.

C. Overview of the Article

This article will explore the various types of shunt capacitors, their applications, materials used in their construction, key specifications, and current trends in technology. By understanding these aspects, readers will gain insight into the importance of shunt capacitors in both industrial and residential settings.

II. Types of Shunt Capacitors

A. Fixed Shunt Capacitors

1. Description and Functionality

Fixed shunt capacitors are designed to provide a constant amount of reactive power compensation. They are typically used in applications where the load is stable and predictable. These capacitors are straightforward in design and do not require any adjustments once installed.

2. Common Applications

Fixed shunt capacitors are commonly used in industrial plants, commercial buildings, and substations to improve power factor and voltage stability. They are often found in motor applications, lighting systems, and HVAC systems.

3. Advantages and Disadvantages

**Advantages:**

- Simple installation and operation

- Cost-effective for stable loads

- Reliable performance

**Disadvantages:**

- Limited flexibility for varying loads

- Potential for overcompensation during low load conditions

B. Variable Shunt Capacitors

1. Description and Functionality

Variable shunt capacitors allow for adjustable reactive power compensation. They can be manually or automatically adjusted to match the changing load conditions, making them suitable for applications with fluctuating power demands.

2. Common Applications

These capacitors are often used in applications such as industrial machinery, where load conditions can vary significantly throughout the day. They are also used in power distribution systems to maintain optimal power factor levels.

3. Advantages and Disadvantages

**Advantages:**

- Flexibility to adjust to changing loads

- Improved efficiency in dynamic applications

**Disadvantages:**

- More complex and expensive than fixed capacitors

- Requires regular maintenance and monitoring

C. Automatic Shunt Capacitors

1. Description and Functionality

Automatic shunt capacitors are equipped with control systems that automatically adjust the capacitor bank's output based on real-time load conditions. This technology allows for optimal power factor correction without manual intervention.

2. Common Applications

These capacitors are widely used in large industrial facilities, commercial buildings, and utility companies where load conditions can change rapidly. They are particularly beneficial in environments with variable loads, such as manufacturing plants and data centers.

3. Advantages and Disadvantages

**Advantages:**

- Real-time adjustment for optimal performance

- Reduced need for manual monitoring and maintenance

**Disadvantages:**

- Higher initial investment costs

- Complexity in installation and setup

D. Power Factor Correction Capacitors

1. Description and Functionality

Power factor correction capacitors are specifically designed to improve the power factor of electrical systems. They work by supplying reactive power to the system, thereby reducing the amount of reactive power drawn from the grid.

2. Common Applications

These capacitors are commonly used in industrial and commercial settings, particularly in applications with inductive loads such as motors, transformers, and lighting systems.

3. Advantages and Disadvantages

**Advantages:**

- Significant reduction in energy costs

- Improved system efficiency and reliability

**Disadvantages:**

- Potential for resonance issues if not properly sized

- Requires careful planning and analysis for installation

E. Harmonic Filter Capacitors

1. Description and Functionality

Harmonic filter capacitors are designed to mitigate the effects of harmonic distortion in electrical systems. They work by filtering out unwanted harmonic frequencies, improving the overall power quality.

2. Common Applications

These capacitors are often used in industrial applications with non-linear loads, such as variable frequency drives (VFDs) and rectifiers, where harmonic distortion can be a significant issue.

3. Advantages and Disadvantages

**Advantages:**

- Improved power quality and system performance

- Reduction in equipment overheating and failures

**Disadvantages:**

- Higher complexity and cost

- Requires careful design and implementation

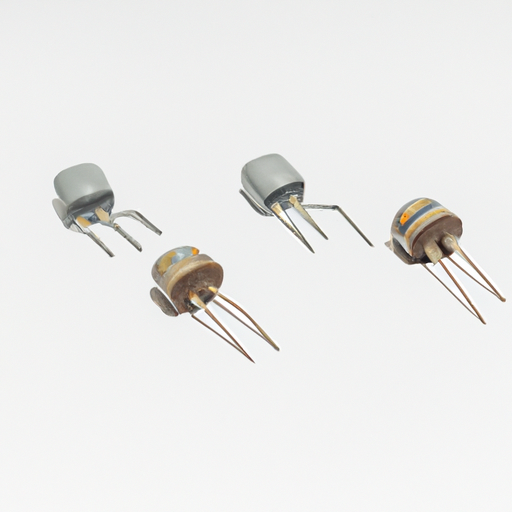

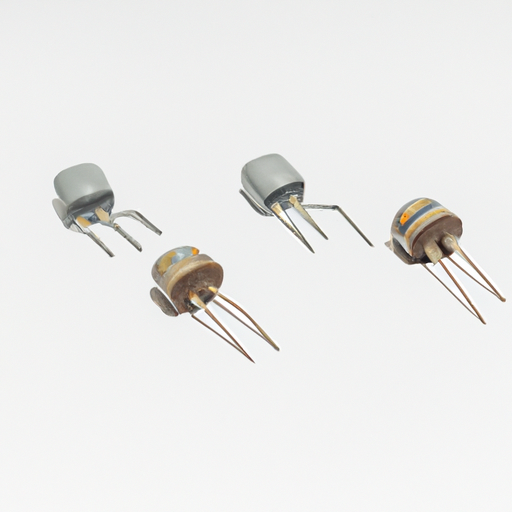

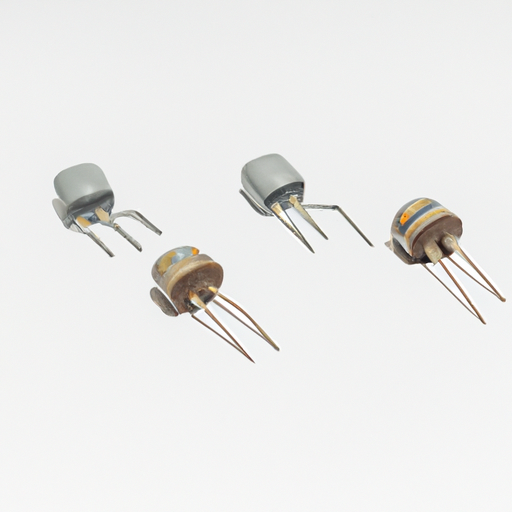

III. Materials Used in Shunt Capacitors

A. Aluminum Electrolytic Capacitors

Aluminum electrolytic capacitors are widely used in shunt capacitor applications due to their high capacitance values and relatively low cost. They are suitable for applications requiring bulk capacitance but have limitations in terms of voltage ratings and temperature stability.

B. Film Capacitors

Film capacitors are known for their stability and reliability. They are often used in power factor correction applications due to their low losses and high voltage ratings. They are also resistant to environmental factors, making them suitable for outdoor installations.

C. Ceramic Capacitors

Ceramic capacitors are compact and offer excellent performance in high-frequency applications. They are often used in smaller shunt capacitor designs but may not provide the same capacitance values as electrolytic or film capacitors.

D. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance and voltage ratings in a small package. They are used in specialized applications where size and performance are critical, although they tend to be more expensive than other types.

IV. Key Specifications and Ratings

A. Voltage Rating

The voltage rating of a shunt capacitor indicates the maximum voltage the capacitor can handle without failure. It is crucial to select a capacitor with an appropriate voltage rating for the specific application to ensure safety and reliability.

B. Capacitance Value

The capacitance value determines the amount of reactive power the capacitor can provide. It is essential to calculate the required capacitance based on the load characteristics and power factor correction needs.

C. Temperature Coefficient

The temperature coefficient indicates how the capacitance value changes with temperature. Selecting capacitors with suitable temperature coefficients is important for maintaining performance in varying environmental conditions.

D. Ripple Current Rating

The ripple current rating specifies the maximum AC current the capacitor can handle without overheating. This rating is particularly important in applications with fluctuating loads and can impact the longevity of the capacitor.

V. Applications of Shunt Capacitors

A. Industrial Applications

In industrial settings, shunt capacitors are used to improve power factor, reduce energy costs, and enhance the performance of machinery and equipment. They are commonly found in manufacturing plants, processing facilities, and large-scale operations.

B. Commercial Applications

Commercial buildings utilize shunt capacitors to manage energy costs and improve the efficiency of lighting, HVAC systems, and other electrical loads. Proper power factor correction can lead to significant savings on utility bills.

C. Residential Applications

In residential settings, shunt capacitors can be used to improve the efficiency of home appliances and reduce energy consumption. They are particularly beneficial in homes with multiple inductive loads, such as air conditioning units and refrigerators.

D. Renewable Energy Systems

Shunt capacitors play a crucial role in renewable energy systems, such as solar and wind power installations. They help to stabilize voltage levels and improve the overall efficiency of energy conversion and distribution.

VI. Trends and Innovations in Shunt Capacitor Technology

A. Smart Capacitors

The integration of smart technology into shunt capacitors allows for real-time monitoring and control. Smart capacitors can automatically adjust their output based on load conditions, providing enhanced efficiency and performance.

B. Eco-Friendly Materials

As environmental concerns grow, manufacturers are exploring eco-friendly materials for shunt capacitors. This includes the use of biodegradable materials and sustainable manufacturing processes to reduce the environmental impact.

C. Enhanced Efficiency and Performance

Ongoing research and development in capacitor technology are leading to improved efficiency and performance. Innovations in materials and design are enabling capacitors to handle higher loads, operate at higher temperatures, and provide better power quality.

VII. Conclusion

A. Summary of Key Points

Shunt capacitors are essential components in modern electrical systems, providing reactive power compensation and improving power factor. Various types of shunt capacitors, including fixed, variable, automatic, power factor correction, and harmonic filter capacitors, serve different applications and offer unique advantages and disadvantages.

B. Future Outlook for Shunt Capacitor Products

As technology continues to advance, the future of shunt capacitors looks promising. Innovations in smart technology, eco-friendly materials, and enhanced performance will drive the development of more efficient and reliable capacitor solutions.

C. Final Thoughts on the Importance of Shunt Capacitors in Modern Electrical Systems

In conclusion, shunt capacitors play a vital role in ensuring the efficiency and reliability of electrical systems across various applications. Understanding the different types, materials, and specifications of shunt capacitors is essential for optimizing their use and maximizing their benefits in both industrial and residential settings.

VIII. References

A. Academic Journals

- IEEE Transactions on Power Electronics

- Journal of Electrical Engineering & Technology

B. Industry Reports

- International Energy Agency (IEA) Reports

- Power Factor Correction Market Analysis

C. Manufacturer Specifications

- Capacitor manufacturers' technical datasheets

- Industry standards and guidelines

D. Online Resources and Articles

- Electrical Engineering Portal

- Energy Efficiency and Renewable Energy (EERE) Resources

This comprehensive overview of shunt capacitors highlights their significance in electrical systems and provides valuable insights into their types, applications, and future trends. Understanding these components is crucial for anyone involved in electrical engineering, energy management, or related fields.

What are the Popular Shunt Capacitor Product Types?

I. Introduction

A. Definition of Shunt Capacitors

Shunt capacitors are electrical components that are used to improve the power factor in electrical systems. They are connected in parallel (or "shunt") with the load, providing reactive power compensation. This helps to reduce the overall demand for reactive power from the grid, leading to improved efficiency and reduced energy costs.

B. Importance of Shunt Capacitors in Electrical Systems

In modern electrical systems, maintaining an optimal power factor is crucial for efficient operation. Poor power factor can lead to increased energy losses, higher electricity bills, and potential penalties from utility companies. Shunt capacitors play a vital role in correcting power factor issues, enhancing voltage stability, and improving the overall performance of electrical systems.

C. Overview of the Article

This article will explore the various types of shunt capacitors, their applications, materials used in their construction, key specifications, and current trends in technology. By understanding these aspects, readers will gain insight into the importance of shunt capacitors in both industrial and residential settings.

II. Types of Shunt Capacitors

A. Fixed Shunt Capacitors

1. Description and Functionality

Fixed shunt capacitors are designed to provide a constant amount of reactive power compensation. They are typically used in applications where the load is stable and predictable. These capacitors are straightforward in design and do not require any adjustments once installed.

2. Common Applications

Fixed shunt capacitors are commonly used in industrial plants, commercial buildings, and substations to improve power factor and voltage stability. They are often found in motor applications, lighting systems, and HVAC systems.

3. Advantages and Disadvantages

**Advantages:**

- Simple installation and operation

- Cost-effective for stable loads

- Reliable performance

**Disadvantages:**

- Limited flexibility for varying loads

- Potential for overcompensation during low load conditions

B. Variable Shunt Capacitors

1. Description and Functionality

Variable shunt capacitors allow for adjustable reactive power compensation. They can be manually or automatically adjusted to match the changing load conditions, making them suitable for applications with fluctuating power demands.

2. Common Applications

These capacitors are often used in applications such as industrial machinery, where load conditions can vary significantly throughout the day. They are also used in power distribution systems to maintain optimal power factor levels.

3. Advantages and Disadvantages

**Advantages:**

- Flexibility to adjust to changing loads

- Improved efficiency in dynamic applications

**Disadvantages:**

- More complex and expensive than fixed capacitors

- Requires regular maintenance and monitoring

C. Automatic Shunt Capacitors

1. Description and Functionality

Automatic shunt capacitors are equipped with control systems that automatically adjust the capacitor bank's output based on real-time load conditions. This technology allows for optimal power factor correction without manual intervention.

2. Common Applications

These capacitors are widely used in large industrial facilities, commercial buildings, and utility companies where load conditions can change rapidly. They are particularly beneficial in environments with variable loads, such as manufacturing plants and data centers.

3. Advantages and Disadvantages

**Advantages:**

- Real-time adjustment for optimal performance

- Reduced need for manual monitoring and maintenance

**Disadvantages:**

- Higher initial investment costs

- Complexity in installation and setup

D. Power Factor Correction Capacitors

1. Description and Functionality

Power factor correction capacitors are specifically designed to improve the power factor of electrical systems. They work by supplying reactive power to the system, thereby reducing the amount of reactive power drawn from the grid.

2. Common Applications

These capacitors are commonly used in industrial and commercial settings, particularly in applications with inductive loads such as motors, transformers, and lighting systems.

3. Advantages and Disadvantages

**Advantages:**

- Significant reduction in energy costs

- Improved system efficiency and reliability

**Disadvantages:**

- Potential for resonance issues if not properly sized

- Requires careful planning and analysis for installation

E. Harmonic Filter Capacitors

1. Description and Functionality

Harmonic filter capacitors are designed to mitigate the effects of harmonic distortion in electrical systems. They work by filtering out unwanted harmonic frequencies, improving the overall power quality.

2. Common Applications

These capacitors are often used in industrial applications with non-linear loads, such as variable frequency drives (VFDs) and rectifiers, where harmonic distortion can be a significant issue.

3. Advantages and Disadvantages

**Advantages:**

- Improved power quality and system performance

- Reduction in equipment overheating and failures

**Disadvantages:**

- Higher complexity and cost

- Requires careful design and implementation

III. Materials Used in Shunt Capacitors

A. Aluminum Electrolytic Capacitors

Aluminum electrolytic capacitors are widely used in shunt capacitor applications due to their high capacitance values and relatively low cost. They are suitable for applications requiring bulk capacitance but have limitations in terms of voltage ratings and temperature stability.

B. Film Capacitors

Film capacitors are known for their stability and reliability. They are often used in power factor correction applications due to their low losses and high voltage ratings. They are also resistant to environmental factors, making them suitable for outdoor installations.

C. Ceramic Capacitors

Ceramic capacitors are compact and offer excellent performance in high-frequency applications. They are often used in smaller shunt capacitor designs but may not provide the same capacitance values as electrolytic or film capacitors.

D. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance and voltage ratings in a small package. They are used in specialized applications where size and performance are critical, although they tend to be more expensive than other types.

IV. Key Specifications and Ratings

A. Voltage Rating

The voltage rating of a shunt capacitor indicates the maximum voltage the capacitor can handle without failure. It is crucial to select a capacitor with an appropriate voltage rating for the specific application to ensure safety and reliability.

B. Capacitance Value

The capacitance value determines the amount of reactive power the capacitor can provide. It is essential to calculate the required capacitance based on the load characteristics and power factor correction needs.

C. Temperature Coefficient

The temperature coefficient indicates how the capacitance value changes with temperature. Selecting capacitors with suitable temperature coefficients is important for maintaining performance in varying environmental conditions.

D. Ripple Current Rating

The ripple current rating specifies the maximum AC current the capacitor can handle without overheating. This rating is particularly important in applications with fluctuating loads and can impact the longevity of the capacitor.

V. Applications of Shunt Capacitors

A. Industrial Applications

In industrial settings, shunt capacitors are used to improve power factor, reduce energy costs, and enhance the performance of machinery and equipment. They are commonly found in manufacturing plants, processing facilities, and large-scale operations.

B. Commercial Applications

Commercial buildings utilize shunt capacitors to manage energy costs and improve the efficiency of lighting, HVAC systems, and other electrical loads. Proper power factor correction can lead to significant savings on utility bills.

C. Residential Applications

In residential settings, shunt capacitors can be used to improve the efficiency of home appliances and reduce energy consumption. They are particularly beneficial in homes with multiple inductive loads, such as air conditioning units and refrigerators.

D. Renewable Energy Systems

Shunt capacitors play a crucial role in renewable energy systems, such as solar and wind power installations. They help to stabilize voltage levels and improve the overall efficiency of energy conversion and distribution.

VI. Trends and Innovations in Shunt Capacitor Technology

A. Smart Capacitors

The integration of smart technology into shunt capacitors allows for real-time monitoring and control. Smart capacitors can automatically adjust their output based on load conditions, providing enhanced efficiency and performance.

B. Eco-Friendly Materials

As environmental concerns grow, manufacturers are exploring eco-friendly materials for shunt capacitors. This includes the use of biodegradable materials and sustainable manufacturing processes to reduce the environmental impact.

C. Enhanced Efficiency and Performance

Ongoing research and development in capacitor technology are leading to improved efficiency and performance. Innovations in materials and design are enabling capacitors to handle higher loads, operate at higher temperatures, and provide better power quality.

VII. Conclusion

A. Summary of Key Points

Shunt capacitors are essential components in modern electrical systems, providing reactive power compensation and improving power factor. Various types of shunt capacitors, including fixed, variable, automatic, power factor correction, and harmonic filter capacitors, serve different applications and offer unique advantages and disadvantages.

B. Future Outlook for Shunt Capacitor Products

As technology continues to advance, the future of shunt capacitors looks promising. Innovations in smart technology, eco-friendly materials, and enhanced performance will drive the development of more efficient and reliable capacitor solutions.

C. Final Thoughts on the Importance of Shunt Capacitors in Modern Electrical Systems

In conclusion, shunt capacitors play a vital role in ensuring the efficiency and reliability of electrical systems across various applications. Understanding the different types, materials, and specifications of shunt capacitors is essential for optimizing their use and maximizing their benefits in both industrial and residential settings.

VIII. References

A. Academic Journals

- IEEE Transactions on Power Electronics

- Journal of Electrical Engineering & Technology

B. Industry Reports

- International Energy Agency (IEA) Reports

- Power Factor Correction Market Analysis

C. Manufacturer Specifications

- Capacitor manufacturers' technical datasheets

- Industry standards and guidelines

D. Online Resources and Articles

- Electrical Engineering Portal

- Energy Efficiency and Renewable Energy (EERE) Resources

This comprehensive overview of shunt capacitors highlights their significance in electrical systems and provides valuable insights into their types, applications, and future trends. Understanding these components is crucial for anyone involved in electrical engineering, energy management, or related fields.