Market Policies for Capacitors: Navigating the Landscape

I. Introduction

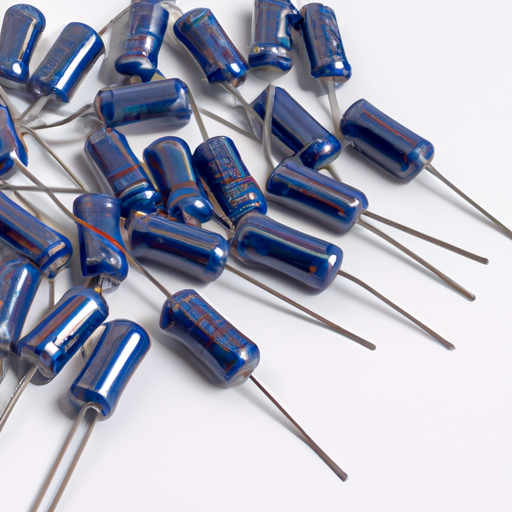

Capacitors are essential electronic components that store and release electrical energy, playing a crucial role in various applications, from consumer electronics to industrial machinery. As the demand for capacitors continues to grow, driven by advancements in technology and the increasing prevalence of electronic devices, understanding the market policies that govern this industry becomes paramount. This blog post will explore the regulatory framework, market structure, pricing policies, trade dynamics, innovation, and sustainability efforts that shape the capacitor market.

II. Regulatory Framework

A. National and International Standards

The capacitor industry is governed by a complex web of national and international standards that ensure product safety, reliability, and environmental compliance. Key organizations such as the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) set forth guidelines that manufacturers must adhere to. These standards cover various aspects, including performance specifications, testing methods, and safety requirements.

Additionally, regulations like the Restriction of Hazardous Substances (RoHS) directive play a significant role in shaping the capacitor market. RoHS restricts the use of certain hazardous materials in electrical and electronic equipment, compelling manufacturers to adopt safer materials and processes.

B. Compliance Requirements for Manufacturers

Manufacturers in the capacitor industry must navigate a myriad of compliance requirements to ensure their products meet regulatory standards. Quality assurance and rigorous testing are essential components of this process. Capacitors must undergo extensive testing to verify their performance, reliability, and safety before they can be marketed.

Environmental regulations also impose strict guidelines on manufacturing processes, requiring companies to minimize waste and emissions. Compliance with these regulations can be costly and time-consuming, impacting market entry and competition. However, adherence to these standards ultimately enhances product quality and consumer trust.

C. Impact of Regulations on Market Entry and Competition

The regulatory landscape can create barriers to entry for new players in the capacitor market. Established manufacturers often have the resources and expertise to navigate complex compliance requirements, giving them a competitive edge. However, these regulations also promote innovation and drive companies to improve their products, benefiting consumers in the long run.

III. Market Structure

A. Types of Capacitors and Their Applications

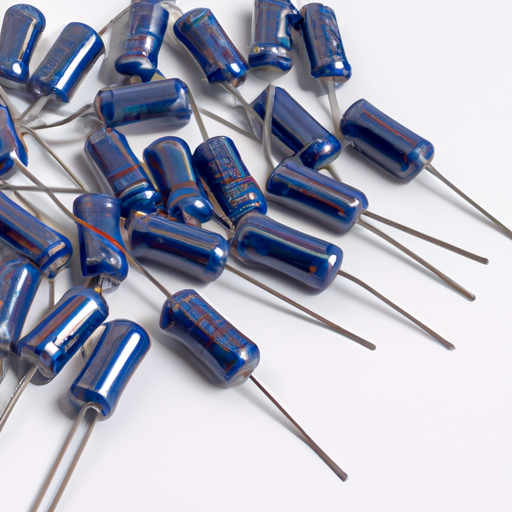

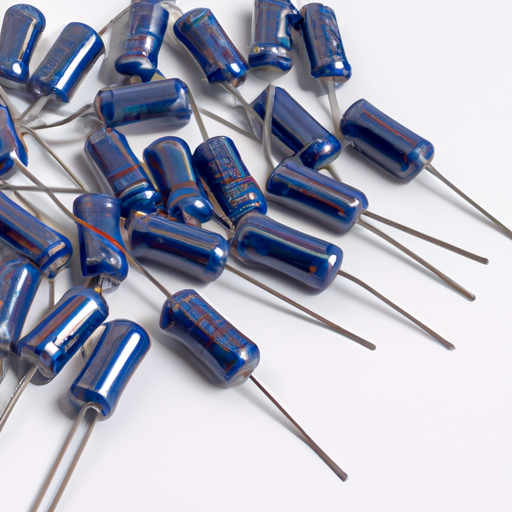

The capacitor market is diverse, with various types of capacitors serving different applications. Electrolytic capacitors, known for their high capacitance values, are commonly used in power supply circuits. Ceramic capacitors, valued for their stability and reliability, find applications in high-frequency circuits. Film capacitors, with their excellent performance characteristics, are often used in audio and power electronics.

B. Key Players in the Capacitor Market

The capacitor market is characterized by a mix of major manufacturers and emerging companies. Established players like Murata Manufacturing, Vishay Intertechnology, and KEMET Corporation dominate the market, leveraging their extensive experience and resources. However, new entrants are also making their mark, often focusing on niche markets or innovative technologies.

C. Market Segmentation

The capacitor market can be segmented by type, application, and region. By type, the market includes electrolytic, ceramic, film, and tantalum capacitors, each catering to specific needs. Applications range from consumer electronics to automotive and industrial sectors. Regionally, the market is divided into North America, Europe, Asia-Pacific, and other regions, with Asia-Pacific being a significant hub for capacitor manufacturing.

IV. Pricing Policies

A. Factors Influencing Capacitor Pricing

Several factors influence the pricing of capacitors, including raw material costs, manufacturing processes, and supply chain dynamics. The prices of materials such as aluminum, tantalum, and ceramics can fluctuate significantly, impacting overall production costs. Additionally, advancements in manufacturing technologies can lead to cost reductions, allowing manufacturers to offer competitive pricing.

B. Pricing Strategies Employed by Manufacturers

Manufacturers employ various pricing strategies to remain competitive in the capacitor market. Cost-plus pricing involves calculating the total production cost and adding a markup for profit. Competitive pricing focuses on setting prices based on competitors' rates, while value-based pricing considers the perceived value of the product to the customer. Each strategy has its advantages and challenges, and manufacturers must carefully assess market conditions to determine the most effective approach.

C. Impact of Pricing on Market Competition

Pricing policies play a crucial role in shaping market competition. Competitive pricing can lead to price wars, eroding profit margins for manufacturers. Conversely, value-based pricing can help companies differentiate their products and maintain healthy margins. Ultimately, pricing strategies must align with market demand and consumer preferences to ensure long-term success.

V. Trade Policies

A. Tariffs and Trade Barriers

Trade policies significantly impact the capacitor market, with tariffs and trade barriers influencing import and export dynamics. Countries may impose tariffs on imported capacitors to protect domestic manufacturers, affecting pricing and availability. Additionally, trade agreements can facilitate smoother trade flows, benefiting manufacturers and consumers alike.

B. Impact of Globalization on Capacitor Trade

Globalization has transformed the capacitor market, enabling manufacturers to outsource production to countries with lower labor costs. This shift has led to increased competition and a more interconnected supply chain. However, it also poses challenges, such as navigating different regulatory environments and managing risks associated with international trade.

C. Case Studies of Trade Disputes in the Capacitor Industry

The capacitor industry has witnessed trade disputes that highlight the complexities of international trade. For instance, disputes over tariffs on imported capacitors have arisen between major economies, impacting manufacturers and consumers. These cases underscore the importance of understanding trade policies and their implications for the capacitor market.

VI. Innovation and Technology Policies

A. Role of Research and Development in the Capacitor Market

Innovation is a driving force in the capacitor market, with research and development (R&D) playing a critical role in advancing technology. Manufacturers invest in R&D to develop new capacitor designs, improve performance, and enhance reliability. This focus on innovation is essential for staying competitive in a rapidly evolving market.

B. Government Incentives for Innovation

Governments often provide incentives to encourage innovation in the capacitor industry. Grants and funding for R&D initiatives can help manufacturers explore new technologies and materials. Additionally, tax incentives for technology advancements can further stimulate investment in innovation, fostering a culture of continuous improvement.

C. Impact of Technological Advancements on Market Dynamics

Technological advancements have a profound impact on market dynamics, influencing product development, manufacturing processes, and consumer preferences. As new technologies emerge, manufacturers must adapt to changing market demands and invest in innovative solutions to remain competitive.

VII. Sustainability and Environmental Policies

A. Growing Emphasis on Sustainable Practices

Sustainability has become a key focus in the capacitor industry, with manufacturers increasingly adopting eco-friendly materials and manufacturing processes. The push for sustainability is driven by consumer demand for environmentally responsible products and regulatory pressures to minimize environmental impact.

B. Corporate Social Responsibility (CSR) in the Capacitor Industry

Corporate social responsibility (CSR) initiatives are gaining traction in the capacitor industry, with companies recognizing the importance of ethical practices and community engagement. Manufacturers are increasingly committed to sustainable sourcing, waste reduction, and social initiatives that benefit local communities.

C. Future Trends in Sustainability Policies

As sustainability becomes a priority for consumers and regulators alike, the capacitor industry is likely to see continued emphasis on eco-friendly practices. Future trends may include increased use of recyclable materials, energy-efficient manufacturing processes, and greater transparency in supply chains.

VIII. Conclusion

In conclusion, the capacitor market is shaped by a complex interplay of regulatory frameworks, market structures, pricing policies, trade dynamics, innovation, and sustainability efforts. Understanding these market policies is essential for industry stakeholders, as they navigate the challenges and opportunities within this dynamic landscape. As the demand for capacitors continues to grow, adapting to changing market policies will be crucial for manufacturers, consumers, and policymakers alike. The future of the capacitor market holds promise, driven by innovation and a commitment to sustainability, ensuring that this vital industry remains at the forefront of technological advancement.

Market Policies for Capacitors: Navigating the Landscape

I. Introduction

Capacitors are essential electronic components that store and release electrical energy, playing a crucial role in various applications, from consumer electronics to industrial machinery. As the demand for capacitors continues to grow, driven by advancements in technology and the increasing prevalence of electronic devices, understanding the market policies that govern this industry becomes paramount. This blog post will explore the regulatory framework, market structure, pricing policies, trade dynamics, innovation, and sustainability efforts that shape the capacitor market.

II. Regulatory Framework

A. National and International Standards

The capacitor industry is governed by a complex web of national and international standards that ensure product safety, reliability, and environmental compliance. Key organizations such as the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) set forth guidelines that manufacturers must adhere to. These standards cover various aspects, including performance specifications, testing methods, and safety requirements.

Additionally, regulations like the Restriction of Hazardous Substances (RoHS) directive play a significant role in shaping the capacitor market. RoHS restricts the use of certain hazardous materials in electrical and electronic equipment, compelling manufacturers to adopt safer materials and processes.

B. Compliance Requirements for Manufacturers

Manufacturers in the capacitor industry must navigate a myriad of compliance requirements to ensure their products meet regulatory standards. Quality assurance and rigorous testing are essential components of this process. Capacitors must undergo extensive testing to verify their performance, reliability, and safety before they can be marketed.

Environmental regulations also impose strict guidelines on manufacturing processes, requiring companies to minimize waste and emissions. Compliance with these regulations can be costly and time-consuming, impacting market entry and competition. However, adherence to these standards ultimately enhances product quality and consumer trust.

C. Impact of Regulations on Market Entry and Competition

The regulatory landscape can create barriers to entry for new players in the capacitor market. Established manufacturers often have the resources and expertise to navigate complex compliance requirements, giving them a competitive edge. However, these regulations also promote innovation and drive companies to improve their products, benefiting consumers in the long run.

III. Market Structure

A. Types of Capacitors and Their Applications

The capacitor market is diverse, with various types of capacitors serving different applications. Electrolytic capacitors, known for their high capacitance values, are commonly used in power supply circuits. Ceramic capacitors, valued for their stability and reliability, find applications in high-frequency circuits. Film capacitors, with their excellent performance characteristics, are often used in audio and power electronics.

B. Key Players in the Capacitor Market

The capacitor market is characterized by a mix of major manufacturers and emerging companies. Established players like Murata Manufacturing, Vishay Intertechnology, and KEMET Corporation dominate the market, leveraging their extensive experience and resources. However, new entrants are also making their mark, often focusing on niche markets or innovative technologies.

C. Market Segmentation

The capacitor market can be segmented by type, application, and region. By type, the market includes electrolytic, ceramic, film, and tantalum capacitors, each catering to specific needs. Applications range from consumer electronics to automotive and industrial sectors. Regionally, the market is divided into North America, Europe, Asia-Pacific, and other regions, with Asia-Pacific being a significant hub for capacitor manufacturing.

IV. Pricing Policies

A. Factors Influencing Capacitor Pricing

Several factors influence the pricing of capacitors, including raw material costs, manufacturing processes, and supply chain dynamics. The prices of materials such as aluminum, tantalum, and ceramics can fluctuate significantly, impacting overall production costs. Additionally, advancements in manufacturing technologies can lead to cost reductions, allowing manufacturers to offer competitive pricing.

B. Pricing Strategies Employed by Manufacturers

Manufacturers employ various pricing strategies to remain competitive in the capacitor market. Cost-plus pricing involves calculating the total production cost and adding a markup for profit. Competitive pricing focuses on setting prices based on competitors' rates, while value-based pricing considers the perceived value of the product to the customer. Each strategy has its advantages and challenges, and manufacturers must carefully assess market conditions to determine the most effective approach.

C. Impact of Pricing on Market Competition

Pricing policies play a crucial role in shaping market competition. Competitive pricing can lead to price wars, eroding profit margins for manufacturers. Conversely, value-based pricing can help companies differentiate their products and maintain healthy margins. Ultimately, pricing strategies must align with market demand and consumer preferences to ensure long-term success.

V. Trade Policies

A. Tariffs and Trade Barriers

Trade policies significantly impact the capacitor market, with tariffs and trade barriers influencing import and export dynamics. Countries may impose tariffs on imported capacitors to protect domestic manufacturers, affecting pricing and availability. Additionally, trade agreements can facilitate smoother trade flows, benefiting manufacturers and consumers alike.

B. Impact of Globalization on Capacitor Trade

Globalization has transformed the capacitor market, enabling manufacturers to outsource production to countries with lower labor costs. This shift has led to increased competition and a more interconnected supply chain. However, it also poses challenges, such as navigating different regulatory environments and managing risks associated with international trade.

C. Case Studies of Trade Disputes in the Capacitor Industry

The capacitor industry has witnessed trade disputes that highlight the complexities of international trade. For instance, disputes over tariffs on imported capacitors have arisen between major economies, impacting manufacturers and consumers. These cases underscore the importance of understanding trade policies and their implications for the capacitor market.

VI. Innovation and Technology Policies

A. Role of Research and Development in the Capacitor Market

Innovation is a driving force in the capacitor market, with research and development (R&D) playing a critical role in advancing technology. Manufacturers invest in R&D to develop new capacitor designs, improve performance, and enhance reliability. This focus on innovation is essential for staying competitive in a rapidly evolving market.

B. Government Incentives for Innovation

Governments often provide incentives to encourage innovation in the capacitor industry. Grants and funding for R&D initiatives can help manufacturers explore new technologies and materials. Additionally, tax incentives for technology advancements can further stimulate investment in innovation, fostering a culture of continuous improvement.

C. Impact of Technological Advancements on Market Dynamics

Technological advancements have a profound impact on market dynamics, influencing product development, manufacturing processes, and consumer preferences. As new technologies emerge, manufacturers must adapt to changing market demands and invest in innovative solutions to remain competitive.

VII. Sustainability and Environmental Policies

A. Growing Emphasis on Sustainable Practices

Sustainability has become a key focus in the capacitor industry, with manufacturers increasingly adopting eco-friendly materials and manufacturing processes. The push for sustainability is driven by consumer demand for environmentally responsible products and regulatory pressures to minimize environmental impact.

B. Corporate Social Responsibility (CSR) in the Capacitor Industry

Corporate social responsibility (CSR) initiatives are gaining traction in the capacitor industry, with companies recognizing the importance of ethical practices and community engagement. Manufacturers are increasingly committed to sustainable sourcing, waste reduction, and social initiatives that benefit local communities.

C. Future Trends in Sustainability Policies

As sustainability becomes a priority for consumers and regulators alike, the capacitor industry is likely to see continued emphasis on eco-friendly practices. Future trends may include increased use of recyclable materials, energy-efficient manufacturing processes, and greater transparency in supply chains.

VIII. Conclusion

In conclusion, the capacitor market is shaped by a complex interplay of regulatory frameworks, market structures, pricing policies, trade dynamics, innovation, and sustainability efforts. Understanding these market policies is essential for industry stakeholders, as they navigate the challenges and opportunities within this dynamic landscape. As the demand for capacitors continues to grow, adapting to changing market policies will be crucial for manufacturers, consumers, and policymakers alike. The future of the capacitor market holds promise, driven by innovation and a commitment to sustainability, ensuring that this vital industry remains at the forefront of technological advancement.