Understanding Capacitor Film: An In-Depth Exploration

I. Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. Among the various types of capacitors, film capacitors stand out due to their unique properties and applications. This article aims to provide a comprehensive understanding of capacitor film, exploring its definition, advantages, disadvantages, applications, and future trends in technology.

II. What is a Capacitor?

A capacitor is an electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy.

A. Types of Capacitors

Capacitors come in various types, each with distinct characteristics and applications:

1. **Electrolytic Capacitors**: These capacitors are polarized and typically used for high-capacitance applications, such as power supply filtering.

2. **Ceramic Capacitors**: Known for their small size and stability, ceramic capacitors are widely used in high-frequency applications.

3. **Film Capacitors**: These capacitors utilize thin plastic films as dielectrics and are known for their reliability and performance in various applications.

B. Overview of Capacitor Applications in Electronics

Capacitors are used in a wide range of applications, including power supply circuits, audio equipment, signal coupling and decoupling, timing circuits, and energy storage systems. Their ability to store and release energy makes them essential in both analog and digital electronics.

III. Understanding Film Capacitors

A. Definition of Film Capacitors

Film capacitors are a type of capacitor that uses a thin plastic film as the dielectric material. They are known for their excellent electrical characteristics, stability, and reliability, making them suitable for various applications.

B. Composition and Materials Used in Film Capacitors

Film capacitors are composed of several key materials:

1. **Dielectric Materials**: Common dielectric materials used in film capacitors include:

- **Polyester**: Offers good electrical properties and is cost-effective.

- **Polypropylene**: Known for its low dielectric losses and high insulation resistance.

- **Polycarbonate**: Provides excellent thermal stability and electrical performance.

2. **Metal Foils**: The conductive plates of film capacitors are typically made from metal foils, such as aluminum or copper. These foils are essential for creating the capacitor's electric field and determining its capacitance value.

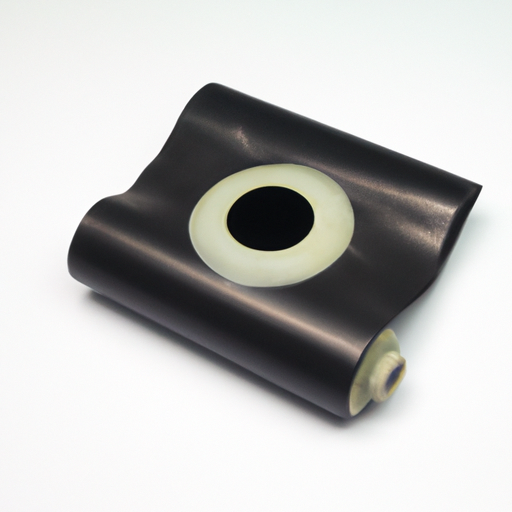

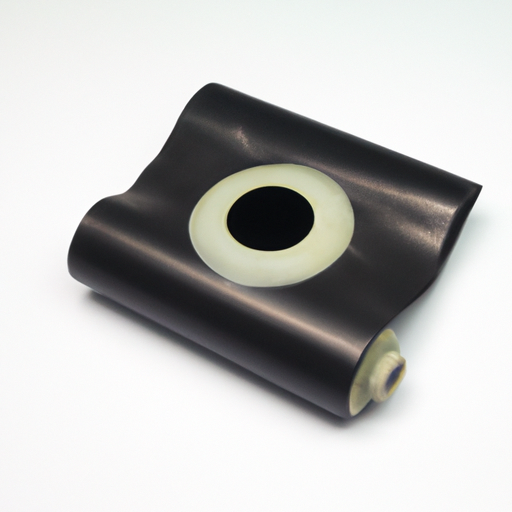

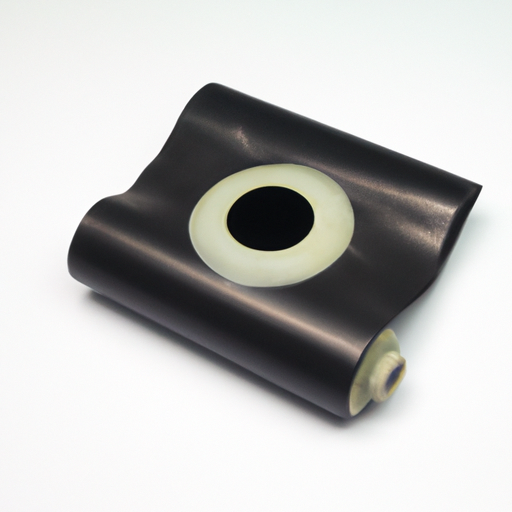

C. Manufacturing Process of Film Capacitors

The manufacturing process of film capacitors involves several steps:

1. **Film Production**: The dielectric film is produced through extrusion or casting processes.

2. **Metalization**: The film is coated with a thin layer of metal, which serves as one of the capacitor's plates.

3. **Winding or Stacking**: The metalized film is either wound into a cylindrical shape or stacked in layers to form the capacitor.

4. **Encapsulation**: The assembled capacitor is encapsulated in a protective material to ensure durability and reliability.

IV. Advantages of Film Capacitors

Film capacitors offer several advantages that make them a popular choice in various applications:

A. Stability and Reliability

Film capacitors exhibit excellent stability over time, with minimal changes in capacitance and dissipation factor. This reliability is crucial in applications where consistent performance is required.

B. Low Self-Inductance

Film capacitors have low self-inductance, making them suitable for high-frequency applications. This characteristic helps reduce signal distortion and improves overall circuit performance.

C. High Insulation Resistance

Film capacitors provide high insulation resistance, which minimizes leakage current and enhances energy efficiency. This property is particularly important in power electronics and energy storage systems.

D. Temperature and Voltage Characteristics

Film capacitors can operate over a wide temperature range and maintain their performance under varying voltage conditions. This versatility makes them suitable for diverse applications, from consumer electronics to industrial machinery.

E. Environmental Considerations

Many film capacitors are made from non-toxic materials, making them environmentally friendly. Additionally, their long lifespan reduces the need for frequent replacements, contributing to sustainability.

V. Disadvantages of Film Capacitors

Despite their advantages, film capacitors also have some drawbacks:

A. Size and Weight Considerations

Film capacitors tend to be larger and heavier than other types of capacitors, such as ceramic or electrolytic capacitors. This can be a limiting factor in applications where space and weight are critical.

B. Cost Factors Compared to Other Capacitor Types

Film capacitors are generally more expensive than electrolytic and ceramic capacitors. This cost difference can be a consideration for manufacturers when selecting components for cost-sensitive applications.

C. Limited Capacitance Values

While film capacitors excel in many areas, they typically have lower capacitance values compared to electrolytic capacitors. This limitation may restrict their use in applications requiring high capacitance.

VI. Applications of Film Capacitors

Film capacitors are used in a wide range of applications, including:

A. Audio Equipment

In audio applications, film capacitors are favored for their low distortion and high-frequency response, making them ideal for coupling and decoupling signals in amplifiers and other audio devices.

B. Power Electronics

Film capacitors are commonly used in power electronics for filtering, energy storage, and power factor correction. Their reliability and performance under varying voltage conditions make them suitable for these applications.

C. Industrial Applications

In industrial settings, film capacitors are used in motor drives, inverters, and other equipment where stability and reliability are essential.

D. Consumer Electronics

Film capacitors are found in various consumer electronics, including televisions, computers, and home appliances, where they help improve performance and energy efficiency.

E. Renewable Energy Systems

Film capacitors play a vital role in renewable energy systems, such as solar inverters, where they are used for energy storage and filtering to ensure efficient operation.

VII. How to Choose the Right Film Capacitor

When selecting a film capacitor for a specific application, several key specifications should be considered:

A. Key Specifications to Consider

1. **Capacitance Value**: The required capacitance value will depend on the specific application and circuit requirements.

2. **Voltage Rating**: Ensure the capacitor can handle the maximum voltage in the circuit to prevent breakdown.

3. **Temperature Coefficient**: Consider the operating temperature range and select a capacitor with appropriate temperature characteristics.

4. **Size and Form Factor**: Evaluate the available space in the application to choose a suitable size and form factor.

B. Application-Specific Considerations

Different applications may have unique requirements, such as low distortion in audio applications or high reliability in industrial settings. Understanding these needs will help in selecting the right capacitor.

C. Common Manufacturers and Brands

Several reputable manufacturers produce high-quality film capacitors, including Vishay, KEMET, WIMA, and Panasonic. Researching and comparing products from these brands can help ensure the selection of a reliable component.

VIII. Future Trends in Film Capacitor Technology

As technology continues to evolve, film capacitors are also experiencing advancements:

A. Innovations in Materials and Manufacturing

Research into new dielectric materials and manufacturing techniques is ongoing, aiming to improve the performance and reduce the cost of film capacitors.

B. The Impact of Emerging Technologies

Emerging technologies, such as electric vehicles and renewable energy systems, are driving demand for advanced capacitors. Film capacitors are well-positioned to meet the needs of these applications due to their reliability and performance.

C. Sustainability and Environmental Impact

With increasing awareness of environmental issues, manufacturers are focusing on producing more sustainable and eco-friendly film capacitors. This trend is likely to continue as the industry moves towards greener practices.

IX. Conclusion

Understanding capacitor film is essential for anyone involved in electronics, from hobbyists to professionals. Film capacitors offer unique advantages, including stability, reliability, and low self-inductance, making them suitable for a wide range of applications. While they have some disadvantages, their benefits often outweigh the drawbacks, especially in critical applications.

As technology advances, film capacitors will continue to play a vital role in modern electronics. By exploring and understanding these components, individuals can make informed decisions when selecting capacitors for their projects and applications.

X. References

For further reading and resources on film capacitors, consider the following:

1. "Capacitors: Technology and Applications" by John Smith

2. "Electronic Components: A Complete Reference" by Jane Doe

3. Industry standards and guidelines from organizations such as the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC).

By delving deeper into the world of capacitors, you can enhance your knowledge and expertise in this essential field of electronics.

Understanding Capacitor Film: An In-Depth Exploration

I. Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. Among the various types of capacitors, film capacitors stand out due to their unique properties and applications. This article aims to provide a comprehensive understanding of capacitor film, exploring its definition, advantages, disadvantages, applications, and future trends in technology.

II. What is a Capacitor?

A capacitor is an electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy.

A. Types of Capacitors

Capacitors come in various types, each with distinct characteristics and applications:

1. **Electrolytic Capacitors**: These capacitors are polarized and typically used for high-capacitance applications, such as power supply filtering.

2. **Ceramic Capacitors**: Known for their small size and stability, ceramic capacitors are widely used in high-frequency applications.

3. **Film Capacitors**: These capacitors utilize thin plastic films as dielectrics and are known for their reliability and performance in various applications.

B. Overview of Capacitor Applications in Electronics

Capacitors are used in a wide range of applications, including power supply circuits, audio equipment, signal coupling and decoupling, timing circuits, and energy storage systems. Their ability to store and release energy makes them essential in both analog and digital electronics.

III. Understanding Film Capacitors

A. Definition of Film Capacitors

Film capacitors are a type of capacitor that uses a thin plastic film as the dielectric material. They are known for their excellent electrical characteristics, stability, and reliability, making them suitable for various applications.

B. Composition and Materials Used in Film Capacitors

Film capacitors are composed of several key materials:

1. **Dielectric Materials**: Common dielectric materials used in film capacitors include:

- **Polyester**: Offers good electrical properties and is cost-effective.

- **Polypropylene**: Known for its low dielectric losses and high insulation resistance.

- **Polycarbonate**: Provides excellent thermal stability and electrical performance.

2. **Metal Foils**: The conductive plates of film capacitors are typically made from metal foils, such as aluminum or copper. These foils are essential for creating the capacitor's electric field and determining its capacitance value.

C. Manufacturing Process of Film Capacitors

The manufacturing process of film capacitors involves several steps:

1. **Film Production**: The dielectric film is produced through extrusion or casting processes.

2. **Metalization**: The film is coated with a thin layer of metal, which serves as one of the capacitor's plates.

3. **Winding or Stacking**: The metalized film is either wound into a cylindrical shape or stacked in layers to form the capacitor.

4. **Encapsulation**: The assembled capacitor is encapsulated in a protective material to ensure durability and reliability.

IV. Advantages of Film Capacitors

Film capacitors offer several advantages that make them a popular choice in various applications:

A. Stability and Reliability

Film capacitors exhibit excellent stability over time, with minimal changes in capacitance and dissipation factor. This reliability is crucial in applications where consistent performance is required.

B. Low Self-Inductance

Film capacitors have low self-inductance, making them suitable for high-frequency applications. This characteristic helps reduce signal distortion and improves overall circuit performance.

C. High Insulation Resistance

Film capacitors provide high insulation resistance, which minimizes leakage current and enhances energy efficiency. This property is particularly important in power electronics and energy storage systems.

D. Temperature and Voltage Characteristics

Film capacitors can operate over a wide temperature range and maintain their performance under varying voltage conditions. This versatility makes them suitable for diverse applications, from consumer electronics to industrial machinery.

E. Environmental Considerations

Many film capacitors are made from non-toxic materials, making them environmentally friendly. Additionally, their long lifespan reduces the need for frequent replacements, contributing to sustainability.

V. Disadvantages of Film Capacitors

Despite their advantages, film capacitors also have some drawbacks:

A. Size and Weight Considerations

Film capacitors tend to be larger and heavier than other types of capacitors, such as ceramic or electrolytic capacitors. This can be a limiting factor in applications where space and weight are critical.

B. Cost Factors Compared to Other Capacitor Types

Film capacitors are generally more expensive than electrolytic and ceramic capacitors. This cost difference can be a consideration for manufacturers when selecting components for cost-sensitive applications.

C. Limited Capacitance Values

While film capacitors excel in many areas, they typically have lower capacitance values compared to electrolytic capacitors. This limitation may restrict their use in applications requiring high capacitance.

VI. Applications of Film Capacitors

Film capacitors are used in a wide range of applications, including:

A. Audio Equipment

In audio applications, film capacitors are favored for their low distortion and high-frequency response, making them ideal for coupling and decoupling signals in amplifiers and other audio devices.

B. Power Electronics

Film capacitors are commonly used in power electronics for filtering, energy storage, and power factor correction. Their reliability and performance under varying voltage conditions make them suitable for these applications.

C. Industrial Applications

In industrial settings, film capacitors are used in motor drives, inverters, and other equipment where stability and reliability are essential.

D. Consumer Electronics

Film capacitors are found in various consumer electronics, including televisions, computers, and home appliances, where they help improve performance and energy efficiency.

E. Renewable Energy Systems

Film capacitors play a vital role in renewable energy systems, such as solar inverters, where they are used for energy storage and filtering to ensure efficient operation.

VII. How to Choose the Right Film Capacitor

When selecting a film capacitor for a specific application, several key specifications should be considered:

A. Key Specifications to Consider

1. **Capacitance Value**: The required capacitance value will depend on the specific application and circuit requirements.

2. **Voltage Rating**: Ensure the capacitor can handle the maximum voltage in the circuit to prevent breakdown.

3. **Temperature Coefficient**: Consider the operating temperature range and select a capacitor with appropriate temperature characteristics.

4. **Size and Form Factor**: Evaluate the available space in the application to choose a suitable size and form factor.

B. Application-Specific Considerations

Different applications may have unique requirements, such as low distortion in audio applications or high reliability in industrial settings. Understanding these needs will help in selecting the right capacitor.

C. Common Manufacturers and Brands

Several reputable manufacturers produce high-quality film capacitors, including Vishay, KEMET, WIMA, and Panasonic. Researching and comparing products from these brands can help ensure the selection of a reliable component.

VIII. Future Trends in Film Capacitor Technology

As technology continues to evolve, film capacitors are also experiencing advancements:

A. Innovations in Materials and Manufacturing

Research into new dielectric materials and manufacturing techniques is ongoing, aiming to improve the performance and reduce the cost of film capacitors.

B. The Impact of Emerging Technologies

Emerging technologies, such as electric vehicles and renewable energy systems, are driving demand for advanced capacitors. Film capacitors are well-positioned to meet the needs of these applications due to their reliability and performance.

C. Sustainability and Environmental Impact

With increasing awareness of environmental issues, manufacturers are focusing on producing more sustainable and eco-friendly film capacitors. This trend is likely to continue as the industry moves towards greener practices.

IX. Conclusion

Understanding capacitor film is essential for anyone involved in electronics, from hobbyists to professionals. Film capacitors offer unique advantages, including stability, reliability, and low self-inductance, making them suitable for a wide range of applications. While they have some disadvantages, their benefits often outweigh the drawbacks, especially in critical applications.

As technology advances, film capacitors will continue to play a vital role in modern electronics. By exploring and understanding these components, individuals can make informed decisions when selecting capacitors for their projects and applications.

X. References

For further reading and resources on film capacitors, consider the following:

1. "Capacitors: Technology and Applications" by John Smith

2. "Electronic Components: A Complete Reference" by Jane Doe

3. Industry standards and guidelines from organizations such as the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC).

By delving deeper into the world of capacitors, you can enhance your knowledge and expertise in this essential field of electronics.